From a jumbled closet stuffed with antique hand planes, axes, and several tools whose purpose remains unclear, David Hoffman produces a wickedly sharp two-man pit saw, about six feet tall. Back in 1790, when a slave or a lumberjack felled a 150-foot bald cypress with an ax, no means existed to haul it out of the woods. You hacked off its limbs and converted its trunk into planks on-site with a saw exactly like this one. Hoffman reckons it’s worth around six hundred dollars, “that is,” he says, “if you can ever find one.”

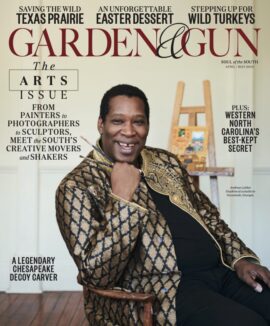

Photo: Sully Sullivan

Hoffman holds a crown molding plane.

Hidden on a shelf amid a cluster of hundred-year-old architectural books, a tiny 1870 Rabone & Sons pocket spirit level catches my eye. The diminutive tool is still perfectly functional—crafted from brass, with its alcohol and air bubble preserved beneath blown glass. The owner of Charleston, South Carolina–based Edgewood Builders, one of the South’s most respected home restoration firms, Hoffman constantly rediscovers gems like this in the nooks and crannies of his collection, which numbers some ten thousand antique tools. He’s tracked them down everywhere from old country stores to the Internet. “When I find them again,” he says, “it’s just like Christmas.”

It’s easy, Hoffman says, to forget that sealing alcohol in a glass bubble required technology that didn’t exist until after the Civil War. Prior to these levels, builders used plumb bobs—weighted balls of brass or lead dangling from a string—to determine not only proper levels, but also to guide bridge builders up their columns and bricklayers up their walls. The weights were often ornately sculpted, and Hoffman’s collection of them is dizzying. “They were absolutely critical,” he says. “And they come in a million variations.”

Photo: Sully Sullivan

A shipwright’s jointer with the owner’s name carved on its side.

Hoffman got his start in the late 1960s in New York’s Hudson Valley, as an eager young apprentice to a gruff master builder from south Georgia named Buster. Amid the valley’s eighteenth- and nineteenth-century buildings, the understudy marveled at the artistry Buster’s calloused hands could impart to crown moldings or windowsill trim with 150-year-old chisels and wooden hand planes. “He was always dangling a half-burned cigarette,” Hoffman says. “And until you proved yourself, he wasn’t going to teach you a damn thing.” As Hoffman’s restoration expertise grew, so did his fascination with the original tools used to build the historic homes he was renovating. When he began landing jobs for clients in Charleston in the late 1970s, that fascination grew into obsession.

He and his wife, Dottie, bought an 1840 fixer-upper on Charleston’s Pitt Street, and he launched into work not only as a restorer of notable homes such as the William Gibbes and Colonel John Ashe houses, but also as a lecturer to homeowners, colleagues, students of the building trade, and the just plain curious.

“When most people hear ‘hand built,’ they think, ‘Oh, they must be out there with a power nailer and a Skilsaw,’” Hoffman says. “They don’t equate it with real blood, sweat, and tears—a pit saw, a broadax, molding planes, handsaws, miters, spirit levels. They built Charleston with these things.”

At first blush, most tools, like the 150-year-old beading plane he’s currently hefting, seem deceptively simple. “My first question is always, what’s the purpose of the tool?” he says. “Second is, well, how do you run it?” It takes a deft, fluid touch to create a perfect 3/16-inch bead or a 16-foot-long crown molding with a hand plane. Hoffman has stacks of these planes, each painstakingly hand cut in a variety of patterns, with blades then wrought by the local blacksmith. They were objects not only of livelihood but also of immense pride, often bearing the name of the maker, owner, or both. Among Hoffman’s most prized pieces is a plane crafted in the mid-1700s, bearing the stamp of Cesar Chelor, a onetime slave owned by a master plane maker from Wrentham, Massachusetts, named Francis Nicholson. When Nicholson died, in 1753, he willed Chelor his freedom, tools, and workshop. Today, Chelor’s best planes can fetch up to ten thousand dollars.

Photo: Sully Sullivan

A bridge maker’s brass plumb bob.

Hoffman could surely build a near-duplicate of his Pitt Street home with the tools in his collection. He does sometimes use them in his restoration work, but they’re also a way to educate others about the craftsmanship that went into each home he restores. “A man going out to build a house here in 1805, you look at the exquisite detail and say, ‘My God, this was all hand done.’ Somebody dropped and cured the timber, the wood was hand cut with a saw, the details were hand carved, and somebody even made the nails—by hand.”

He’s most fascinated with the story the tools tell—or don’t. A strange wooden device bears a series of leaves that fan out like the feathers of a peacock. “I have no idea what it does,” he says. A beautifully wrought brass bevel square reveals a pinch solution to a problem. “The guy needed a washer for one of these screws, so he used an Indian Head penny.”

“See that blacksmith’s stand behind you?” Hoffman asks. “You wonder, who is the man who devised this and why did he think it up? Well, he had a need, he had the skills, so he built it. It got kicked around for years and years and somehow didn’t get destroyed. And then it finally ended up here.”