A few blocks west of the downtown Swansboro, North Carolina, waterfront, off a side street that curls behind a fast-food chain, beyond a long warehouse building where he rents a work space, next to an old Chevrolet Silverado surrounded by weeds, Wyatt Speight Rhue kicks his boot against a log that might be of great value.

“You don’t see a lot of elm around here anymore,” Rhue, wearing work pants and a flannel shirt, says softly. “I’m gonna see what I can do with it.”

The elm log is surrounded by dozens of others—pine, black gum, holly, pecan, plum, magnolia—that Rhue has collected from this low-lying region along Bogue Sound in Eastern North Carolina. The forty-three-year-old woodworker uses only native trees for his turnings for all manner of home goods and furniture, from bowls to consoles, which sell faster than he can produce them at galleries and fairs around the country.

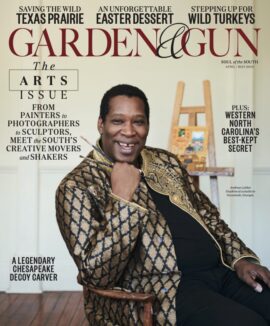

Photo: Geoff Wood

Rhue in his Swansboro, North Carolina wood shop.

This particular elm fell during Hurricane Florence, which soaked Swansboro with more than thirty inches of rain last September. The property owner didn’t want the tree. Rhue didn’t exactly know what to do with it either, but he took it anyway, just to see where it might lead him.

Rhue’s bowls and canisters and other turnings are rustic but refined, each piece highlighting the grains and shapes of materials, imperfections becoming signatures. Most of the wood he turns arrives soaked like a sponge inside (all trees are “wet” when first cut), and as it dries over weeks and months and sometimes years, it expands and changes and cracks. Some transformations are more dramatic than others. Oak, for instance, leaves wedge-shaped cracks that require butterfly joints before finishing to ensure a flush fit. Black gum, which grows in abundance here, is more resilient.

Photo: Geoff Wood

A red maple flower vessel with a hexagonal rim, flanked by two holly vessels.

Rhue speaks with a subdued version of a Down East accent, his vowel sounds a little tighter after spending nearly a decade in Chicago and New York. But he still has the patience that comes from being of this place. He grew up in New Bern, about forty miles north, and spent most of his weekends here; his grandfather had a hardware store downtown along the White Oak River. Rhue’s parents now run an antique shop in the old hardware store space. Rhue’s other grandfather, Marvin Speight, was the longest-serving chairman of the state Alcoholic Beverage Control Commission and a prominent member of North Carolina’s Democratic Party. Rhue remembers going to parties for power players at the family’s house on Indian Beach.

He cares deeply about his family and their roots, but he always felt out of place in the area’s schools. During lunch periods, he’d search out quiet tables where he could draw. An astute teacher recommended the University of North Carolina School of the Arts in Winston-Salem. Rhue transferred his senior year, and immediately things connected. “I felt like a black sheep in New Bern,” he says. “[UNCSA] was a really freeing place to go.”

Photo: Geoff Wood

Rhue shapes a bowl on his lathe.

After graduation, he attended the School of the Art Institute of Chicago, and later landed a job with the prestigious furniture company BDDW in New York, recognized worldwide for its sophisticated pieces made out of natural materials with a minimalist design. About two weeks after he started, Rhue asked BDDW cofounder Joshua Vogel if he could stay late and experiment on the lathe. Vogel, who now has his own studio, looked up and smiled.

“Do you like the lathe?” Vogel asked.

“Yes,” Rhue replied.

“Do you love the lathe?” Vogel countered.

Rhue paused, unsure where this quiz was headed. Vogel continued: “Because sooner or later, you’re either going to hate the lathe or love it. There’s nothing in the middle.”

Rhue has spent the past seventeen or so years giving a resounding answer. His feelings are obvious on a recent morning as he hoists a big slice of that salvaged elm tree up to his lathe in that nondescript building.

Photo: Geoff Wood

From left: A black walnut dresser; more wood containers.

He applies techniques he learned at BDDW to his work today but says he’s always trying to hone his own voice. Place—and the wood native to this place—plays a big role in that fine-tuning. He returned to Swansboro in 2010 and has no plans to leave. Not only is he close to family, but also the cost of living is lower, meaning he can devote more time to the work he loves. Rhue makes elegant furniture, for sure, including a round coffee table that’s one of his best sellers. Those pieces keep his bills paid, although from a creative standpoint, he prefers experimenting with new turnings. Much of his work, for instance, is inspired by pottery he’s come across, from sugar jars to salad bowls. But he favors the process of woodworking over pottery. It’s all about subtraction, cutting away all the parts you don’t want and leaving only those you do.

Photo: Geoff Wood

Chisels at rest in the workshop.

Rhue takes his lathe tool and presses it against the center of the spinning piece of elm, sliding toward the edge as the wheel of wood twirls, applying more force the farther he goes, the shavings piling into the bend in his elbow like a basket of curly fries. Chip, chip, he presses; round, round, the wheel spins. Soon the underside of a bowl reveals itself, and anyone can see the same potential in this elm log that he saw all along.