Virginia belt maker Marcus Wiley remembers the first time he realized his designs had gained a following. It was about ten years ago, when a friend in England e-mailed him a photo of a London real estate agent sporting a Wiley Brothers belt, unmistakably identified by its signature buckle—a curved brass pick originally designed to clean horse hooves.

When you spend most of the day alone in a simple two-room workshop, down a winding country lane amid equestrian estates near Charlottesville, you can forget that people—out there somewhere—are seeking out the luxurious leather pieces you craft by hand. Then again, the photo did close a natural circle, as each Wiley Brothers belt starts with bridle leather sourced from a 114-year-old English tannery, where burly curriers soak cowhide in oak, chestnut, and sumac tannins (plus cod liver oil) to produce an extremely strong and durable final product. “Their primary clientele are saddle and bridle makers, so it has to stand up to wear and tear on a horse,” says Wiley, who grew up on a farm not far from his studio where he learned to ride alongside his English-born mother. “When I was young, all our saddles came from England. The smell of these materials takes me back to the tack room.”

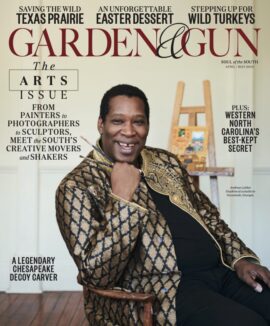

Photo: Michael JN Bowles

Wiley in his shop.

To transform the sheets of leather into belts, Wiley uses a wood-handled strap cutter to neatly slice off premeasured strips known as blanks. This is only the first of fourteen to fifteen exacting steps (many of which involve trimming and stitching tools acquired from an Amish harness-supply company) that earn a belt the Wiley imprint. Nothing is mechanized except the burnishing wheel (which Wiley customized), and even that is hand-fed. It’s an old-fashioned process, but he believes the quality of the finished product justifies the extra effort. “One of my belts will easily last ten to twenty years, if not longer,” Wiley says.

The path the forty-seven-year-old took to becoming a belt maker was considerably less plotted. He worked as a stockbroker and started a publishing business in Colorado before landing back in Virginia, somewhat at loose ends. Meanwhile he began wearing a belt made by a family friend that cleverly employed a hoof pick as a buckle, and stopped counting after a thousand people had complimented it. When the friend passed away, Wiley couldn’t shake the nagging idea that he should continue with the belts, and in 1999 Wiley Brothers was born, with a hand from his sibling Peter.

Of the sixteen styles of buckle stored in a row of pails in Wiley’s workshop, ranging from the original hoof pick to an attention-grabbing sea turtle, more than half are designed and cast in solid brass or white bronze just a few miles away by metalsmith Joe Rhames. Wiley casually mentions that Robert Redford wears the “slip cinch” style, marked by its distinctive circular buckle, in the recent, Oscar-nominated shipwreck drama All Is Lost. Or so he’s been informed—he hasn’t seen the movie yet.

Southern retailers, including Ledbury in Richmond, Sid Mashburn in Atlanta and Houston, and Harrison Limited in Mountain Brook, Alabama, have also taken notice. “We love stocking product that isn’t everywhere, and Wiley belts are a perfect example,” Sid Mashburn says. “You can feel the quality when you touch one.”

Photo: Michael JN Bowles

1 of 6

Photo: Michael JN Bowles

2 of 6

Photo: Michael JN Bowles

3 of 6

Photo: Michael JN Bowles

4 of 6

Photo: Michael JN Bowles

5 of 6

Photo: Michael JN Bowles

6 of 6