In a basement studio off an interstate in Nashville, Ben Caldwell sits behind an oak stump and works. The metalsmith places a U-shaped piece of flat copper on an indentation carved into the stump’s surface, raises a hammer in his left hand, and strikes. Each blow molds the metal, bringing it closer to its destiny as a serving spoon, and simultaneously hardens the copper, which becomes more durable but also less eager to flow into the graceful shapes Caldwell envisions. It’s a craft that demands both brute strength and a fluid touch. “It’s an intuitive thing,” Caldwell says. “There’s kind of an ideal form that I’m looking for.”

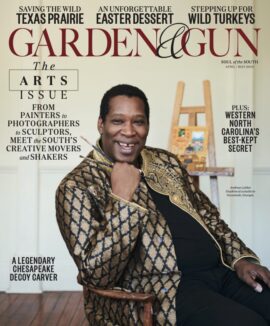

Photo: Caroline Allison

Hammer Time

Caldwell at the anvil in his Nashville workshop.

Over the past seventeen years, Caldwell has consistently found the ideal form with his unique tableware. His spoons, serving pieces, bowls, and platters can be found in galleries from Aspen to Atlanta, in Martha Stewart’s kitchen, and in the Tennessee governor’s residence. His signature pieces pair the elegance of gleaming copper with the rusticity of polished deer, moose, or elk antlers, which he incorporates as handles or bases for bowls. Caldwell likes the natural variations in each antler, and the puzzle-like challenge of selecting a piece of bone that will rest naturally on the table or in the hand. Most of the antlers arrive from a supplier in Montana, but many of Caldwell’s clients are sportsmen who request custom designs using personal pieces. “They will bring me antlers from a special hunt,” he says, “antlers that have a significant emotional connection for them, maybe even antlers that belonged to their grandfathers, and I love to work with them.” All of Caldwell’s pieces have this sense of history and function, right down to the smallest berry spoon. “It has to feel like an old spoon when I’m done,” he says. “It has to feel like it’s one hundred or two hundred years old.”

It’s a standard that Caldwell, who is forty-seven, formed as a boy in Forest Hills, a suburb of Nashville. His father is a collector and amateur scholar of Southern folk art, pottery, and—most important—antique silver, some of which is now housed in the Tennessee State Museum and Nashville’s Cheekwood Museum of Art. “Because of my father,” Caldwell says, “I saw all these artists who were just as good as any artist in New York, but because they were in the South, hardly anyone knew them.”

Growing up around durable, exquisite silver inspired Caldwell’s faith in the unity of design and function, and also provided an uncanny feel for metal. “When I started doing this, it was like, all of a sudden, I knew what a spoon was supposed to look like,” he recalls. “I knew what a ladle was supposed to look like.”

For someone with such a gift, Caldwell came to metalsmithing late. He first trained as a painter and sculptor at Tufts, Harvard, New York Studio School, and the Museum of Fine Arts, Boston. Painting established his sense of design, balance, texture, and depth. He next worked as a luthier and a drum maker, which taught him precision. Caldwell admires the Renaissance masters—Michelangelo and Leonardo da Vinci—who let their creativity roam across disciplines, from poetry and art to architecture and engineering.

In 1997, a master metalsmith named Terry Talley contacted Caldwell’s father. Talley was dying of cancer and looking for a student. Caldwell quit his job and went to train with Talley, a Vietnam veteran turned hippie artist, who worked in a backwoods valley near Bradyville, Tennessee. At night, Caldwell delivered pizzas to support himself and his wife, Lael. Talley wasn’t verbose, but in notes he left to be read at his funeral, he wrote that he trained the “soon-to-be-famous Ben Caldwell,” a compliment his former apprentice treasures.

In Caldwell’s studio, traces of those myriad influences are everywhere. The stump was a gift from Talley. A painting of Christ on the cross is an early Caldwell in classical style. He drinks out of an eighteenth-century English silver cup that his father gave his mother on the day he was born.

The line that’s resulted from Caldwell’s winding path, Ben & Lael, has grown so popular that he now employs apprentices, but his longtime friend and assistant Timothy Blocksom says Caldwell still puts his hands on every Ben & Lael piece—and there are steps he doesn’t entrust to anyone else. Nor does he trust just any off-the-shelf tool. Caldwell built or altered most of the pliers and hammers lining the studio walls; there’s an anvil he fashioned from an old railroad tie, and a rolling press he built to stretch the copper wires that create graceful, looping handles. “His biggest philosophy is ‘Timothy, you’re working too hard,’” Blocksom says. “He wants you to take the time to get it right and not overwork the metal.”

Caldwell also wants to teach his apprentices what Talley taught him: deep appreciation for an art that once flourished in the South. These days metalsmithing is rare; nearly all tableware is factory made. By contrast, Caldwell cuts each shape by hand from sheets of copper, cold forges—or shapes—items with a hammer or a machine he built to help form larger pieces, and joins handles to spoons with a rivet. The last step is buffing and shining. With very large platters and bowls, he uses fire to complete the shaping process. Occasionally, Caldwell makes sterling silver pieces on commission, and fine art ceramic pieces. Either way, the end product is more than a pretty object; it’s an echo of the South’s past.

“I look at part of my responsibility as passing on this knowledge about hand craftsmanship,” he says. “That’s why I teach.” If the sound outside his studio—the bright and steady noise of apprentice hammers striking metal—is any indication, there’s reason to be hopeful.