It was a sad, ruined little sawmill, abandoned probably a half-century earlier in the rhododendron thickets of the Smoky Mountains. Against one of the buckled walls leaned a rusted circular-saw blade that someone had tried to salvage but had never come to claim. If you or I had looked at it, we would have seen several hundred pounds of corroded steel, trying to return to the earth from which it came.

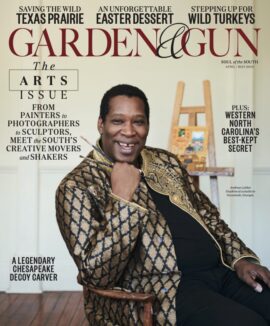

Photo: Cheryl Zibisky

Daniel Winkler at his workshop.

But Daniel Winkler, who lives in the twenty-first century and thinks in the eighteenth, saw knife blades. He is a maker of frontier knives, a smith, and he gets his raw materials the same way his predecessors did three centuries ago: He scrounges. (I once admired a particularly beautiful piece of maple in one of his handles and asked where he got it. “In my woodpile, out back. I was going to burn it, and took a second look.”) That rusted hunk of steel would eventually be cut into knife blades, forged, ground, and polished into a second life.

Winkler, a dark-haired, rangy fifty-three-year-old who keeps his forge in Blowing Rock, North Carolina, recreates knives and tomahawks from the period when America was mostly frontier, and knives—usually big ones—were as common and indispensable as cell phones are today.

He got his start by accident. In 1975, he and his brother bought their father a flintlock rifle, but they couldn’t find the other necessary equipment such as a possibles bag, a powder horn, or a patch knife. So he did what people do in Appalachia if you can’t find it—you make it. Knifemaking especially intrigued him, and he began haunting blacksmith shops to see how it was done. Then he scavenged what he needed from junkyards (his first anvil was a chunk of railroad track) and set to work.

There were, in eighteenth-century America, country blacksmiths who specialized in knives. They made working tools, nothing fancy, but their knives were well thought out, and they are the craftsmen who inspire Dan Winkler, and they would recognize much of what he does, but not all. He beats on steel to shape it, but he does it with a power hammer. He tempers by eye, watching the metal change color until it’s at the right heat, but he gets his heat from propane instead of charcoal. He grinds and polishes, but on machines rather than by hand.

Photo: Cheryl Zibisky

A tomahawk.

He will make for you a belt knife (a general-purpose knife), a bowie, a camp knife (a heavy-duty knife that looks like a modern butcher knife and was favored by mountain men), a folder, a tomahawk, or a patch knife (a small knife, often worn hanging from the neck, to trim flintlock-rifle patches).

Winkler’s knives—no two are alike—are patterned on actual historical models. They look as if they might have been stolen from a museum. Their aura of antiquity is due in large part to Winkler’s partner of twenty-two years and a great artist in her own right, Karen Shook. She makes his sheaths, and a Winkler knife without a Shook sheath is unthinkable. Using rawhide, leather, beads, quills, copper rivets, sinew, and endless ingenuity, she creates works of art that range from dead simple to frontier tour de force.

A Winkler knife begins with a sketch. You go to his Web site, see what you like, and come up with an idea of your own. He will send you a drawing of what you have in mind. If you like what you see, he will get to work. If it’s not what you want, he will sketch some more.

He and Shook have been making knives and sheaths full-time since 1988, and in a business where plenty of gifted people try to make a living and many fail, they are a notable success.

“A lot of makers turn out beautiful knives but have no idea how to promote themselves,” Winkler says. “There are others who fit and finish very well but never develop their own style. I’m a true believer in ‘form follows function.’ When I look at a knife or an ax, I look at the whole piece, follow the lines and how they flow, and then move on to the details. If they’re good, it’s a successful piece. A knife or a tomahawk with proper lines will never lose its appeal and will be comfortable in the hand. But if your eye is drawn to some design detail right off, something is wrong.”

If you’d like to see Winkler’s philosophy brought to life, go to a show where he and Shook have a table. When the show opens, there is a stampede to their spot, much flashing of money, and five minutes later he and Shook are left to sit out the show taking orders, with no knives left to sell. Fine work is appreciated, whether it’s in 2010 or 1810.