One morning in june of 1981, Leonard Bludworth looked out the window of his Leakey, Texas, house and saw a giant motor home lumbering up his driveway. A few minutes later there was a knock on the door. It was the Billiards Congress of America Hall of Famer Cecil P. “Buddy” Hall. He told Bludworth bluntly: “I’m not leaving until you build me a cue.” Bludworth knew Hall from traveling on the pro tour as a pool-cue repairman, but he’d never made a cue from scratch for him—or for anybody else. The cue he made Hall was a stunner: maple shaft, deep V points, and four blue veneers with ebony. And it marked the beginning of Leonard Bludworth’s career as a world-class pool-cue builder.

Since then, Bludworth has built cues for seventeen international pool champions, from Mike Sigel to Steve Mizerak. He’s built them for television stars like Jerry Orbach (of Law and Order fame) and die-hard pool aficionados too. Bludworth is also the first in history to sell a $25,000 cue (commissioned by Grady “the Professor” Mathews), the first to sell a cue for $100,000, and the founder of both the American Cuemakers Association and the Cue Masters.

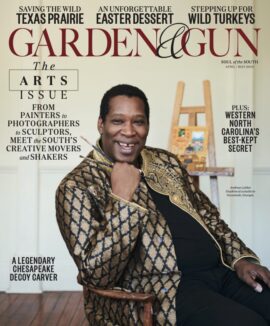

Photo: Brent Humphreys

A row of prized Bludworth cues.

Unfortunately, that record-breaking $100,000 cue was destroyed—cut to pieces with a band saw by an irate wife who caught her husband with his secretary. And they weren’t playing pool. “I suppose it was the first thing that came to her mind,” Bludworth says.

But back before all his success as a cue builder and before Hall showed up on his doorstep, Bludworth had a whole other career, a whole other life. It wasn’t until he had to close his shipyard business in the late 1970s that the idea came to him to put his hobby of playing pool to good use: He packed up his belongings and became the first traveling pool-cue repairman on the pro tour. Bludworth’s customers were the top thirty-two players. “No one knew how to repair cues,” Bludworth says. “I got to be so popular, players would call promoters and say, ‘If Blud can’t come, then we’re not going to show.’” And that’s how he came to know Hall, the player who would one day commission Bludworth’s very first cue.

Over the years, some fifteen thousand cues have been produced and sold inside his 2,800-square-foot shop. In one corner, several cues that never made the “Blud” seal of approval line the wall like hostages.

Photo: Brent Humphreys

Bludworth sizes up a cue.

“They’re good cues too,” Bludworth says, “but if there’s a knot in the wood or a crack in an inlay and it isn’t perfect, it isn’t leaving my shop.”

Bludworth takes an average of eight months to build a cue, and most sell for upwards of $2,000. Selected woods are cured before the shafts are turned and shaped on his customized lathe. Then a pantograph is used to pattern the wood for a variety of inlays, including gold, silver, ivory, abalone, mother-of-pearl, and more. Even the hand-finished grips are available in every material imaginable, from Irish linen to ostrich leather.

All those fancy aesthetics aside, “cue design is just like a woman,” Bludworth says. “You can put on jewelry and it’s real pretty and all, but it’s just skin-deep. You have to go to the heart for a good one.”

So he tests every cue for balance, how it hits, how well it finesses on a table. Depending on the wood type, Bludworth “can make a cue hit real hard like a shock wave going off or make it play so soft it feels like a cushion.” Maple is dense, so the shaft has less flex and hits hard. Bocote, his favorite, “has a sensitive touch, so when you slap-draw the ball you can really feel it.”

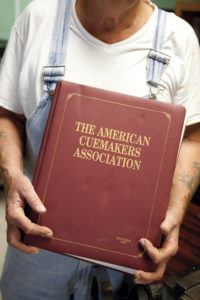

Photo: Brent Humphreys

A copy of the American Cuemakers Association handbook.

Bludworth says people always ask him: “How’s that cue hit?” He laughs. “Well that’s like me asking how you French-kiss. You just don’t know until you test it.”

In the spring of 2008, after almost thirty years in the business and busy with other entrepreneurial endeavors, Bludworth decided to retire—but the hiatus was brief. The day he announced he would continue making custom cues, he had thirty-one orders by nightfall. “I had so many people asking me to make more cues, I thought, heck, it just isn’t right to let them down,” Bludworth says. “It gives me a great deal of satisfaction to make something for people to use for enjoyment and to make a living doing it.”