It started on the way to the grocery store earlier this summer, when I heard a radio ad touting the forty-eight steps behind each tray of Bojangles’ biscuits. Call me old-fashioned, but I could think of maybe a dozen—and that’s being generous. How, I wondered, and why, would a fast-food joint complicate that? Being on the biscuit beat at Garden & Gun, I reached out to Bojangles’ to ask. They wouldn’t share the secrets behind their many steps, but they did offer to let me come in and see how it’s done. So at 8 a.m. on a Saturday in July, I walked into the Bojangles’ in Ladson, South Carolina, where half a dozen locals were already eating breakfast and Bojangles’ Director of Field Training, Debbie Boyette, was waiting with an apron for me.

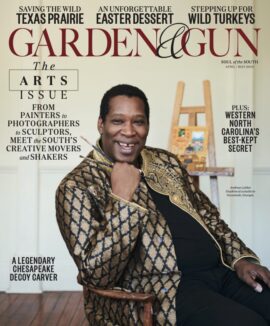

Photo: Courtesy of Bojangles

Debbie Boyette and the author, putting on their aprons.

Here’s what I learned from my morning baking biscuits at Bojangles’:

1. Bojangles’ really does replace its biscuits every twenty minutes, as promised. Usually, though, it’s a lot more often than that.

Standing in the dining room, I watched biscuits disappear like bottled water at a 5K finish line. “There’s no break at breakfast,” Boyette told me. “It’s just bowl after bowl of flour.” According to the company, the average Bojangles’ baker makes more than 1,000 biscuits in an eight-hour shift. That’s an average of at least two biscuits per minute, and more when taking breaks into consideration.

2. Yes, these are scratch-made biscuits.

There’s no denying what I saw when I walked into the kitchen: Ladson baker Devon Graham mixing and working biscuit dough like he’d been turning out thousands of rounds a week for a year, which he had. There’s no faking that skill. Boyette and I started with a bowl of self-rising flour. Next, we cut in vegetable shortening. “We have to make sure the pieces of shortening are a certain size, so they won’t cause craters in the biscuits” Boyette says. Here’s where I start to understand the forty-eight steps. They’re mostly minor, from sifting the flour to shaking the buttermilk to making sure the shortening chunks aren’t too big. They exist to ensure consistency without turning the process over to machines. And there were more to come.

3. Every little bit matters.

Like most home cooks, Bojangles’ biscuit makers mix with their bare hands. (There is, of course, a strict hand-washing policy.) It’s important that they’re able to feel the dough, which can change a little from day to day depending on humidity. Following another step, I scraped the sticky dough off my fingers after mixing in the PET-brand buttermilk. “That could be half a biscuit there on your hand,” Boyette says. Bojangles’ bakers also reuse all the dough scraps left over after they cut out a batch of biscuits, working them into the next one.

4. The recipe never changes, but the technique does.

“Let’s say a biscuit maker came down here from Charlotte, where it’s not as humid,” Boyette says. “If he isn’t getting the feel he wants, he’ll work it more,” developing gluten that helps the dough hold together. Never, though, would he add an extra splash of buttermilk or handful of flour. “The recipe hasn’t changed in fifteen years,” she says.

5. Bojangles’ has perfected the dough fold.

How many times can you fold biscuit dough before you’re doing more harm than good? Southern cooks don’t agree on a number, but the key to delicate, fluffy biscuits is a light touch. Folding helps the dough come together and creates layers, but too much of it strengthens gluten bonds and makes biscuits tough and chewy. I promised not to give away too many trade secrets, but take this one: At Bojangles’, bakers pat the dough into a rough circle and then make just three folds. First, they pull one side of the dough about one-third of the way across the whole thing. Then the other side. Then they roll the dough from the top down to create a firm lump ready to be rolled out and cut.

6. It’s all in the details.

That’s why the process has forty-eight steps—because the folks at Bojangles’ aren’t leaving anything to chance. Corporate expects seasoned bakers to get their biscuits from the mixing bowl to the oven in about four minutes, which leaves plenty of room for error if they aren’t in a step-by-step mindset. There’s even a proprietary process for loading the biscuits onto the baking sheet, with each one of the fifteen biscuits on each sheet assigned a place. Given the number of biscuits I now know this chain sells—75 percent of menu items come with one—I’m not surprised.